Your partner for joining technology

Our joining solutions – as individual as you

Whenever you want to join components, we are at your side as a competent partner. Along your entire value chain. Around the globe. And always with a special focus on the specific requirements of your industry. This all-round service concept is what we call 360° joining technology.

Building Sustainable Connections

Our long-term thinking and responsibility extend beyond business to our planet and society, ensuring a successful future. This commitment forms the core of our corporate philosophy and is reflected in our sustainability strategy.

Our solution for your industry

Each industry is unique. We know the particularities and we develop customized solutions tailor-made, in cooperation with you.

- Automotive

- Aerospace

- Mechanical engineering

- Railway

- Medical technology

- Energy

- Construction industry

- Domestic appliances

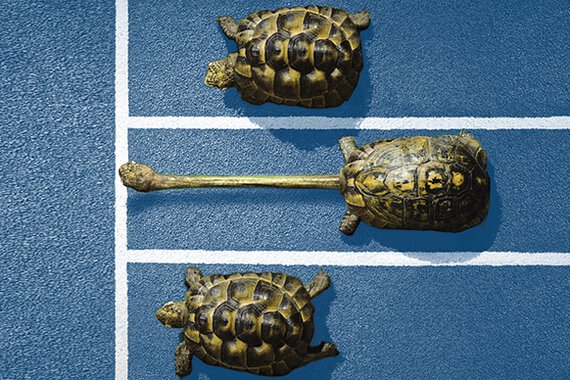

The structural change in the automotive industry is picking up speed. Trend topics, such as lightweight construction, powertrain electrification, autonomous driving and digitalization are complex and challenging. The requirements imposed on joining technology are correspondingly high. New ideas are needed. We have the right answers for contemporary automotive engineering issues

Find out more

We also take a second look and support you in meeting the requirements of current development trends in the aerospace industry. We have been a partner to the industry for decades, providing special joining solutions.

Find out more

Mechanical and plant engineering is one of the most innovative industries. Nevertheless, or perhaps precisely for this reason, structural changes mean that this industry also needs to increase investment in its future competitive ability. We support this industry with innovative fastener solutions and assembly solutions. Whether this involves development and production of large-scale plants, machine tools or special machines.

Find out more

The history of railway technology has fascinated people for centuries. Worldwide, rail traffic volume has never been so high. The requirements that railway operators impose on rail vehicle manufacturers are correspondingly demanding. Whether screws, rivets, clinching or C-Parts management – we offer innovative and reliable solutions.

Find out more

Often the technologies are extremely sensitive, consequently the production requirements are also extremely high. We support you with our custom joining solutions

Find out more

Development of renewable energy is an essential component of environmental protection. This is a top priority for us; with our joining and assembly technology we do our part in shaping the energy future.

Find out more

Construction machines, building material machines and mining machines are deployed in all major construction projects and mining projects around the world. Different weather conditions, permanent force effects through vibration and irregular capacity utilization significantly impact the individual components of these machines. Master these challenges with our reliable joining solutions

Find out more

Networked domestic appliances, low energy consumption and noise reduction play major roles in the manufacturing of domestic appliances. To manage this ever-increasing complexity, integral architectures must be provided. This is where we support you with our joining solutions and assembly solutions

Find out moreTrade fairs, seminars and training courses

Next events

International Fair for Aircraft Interiors

Hall: 6

Booth: C125The benchmark international advanced manufacturing trade show

Shanghai International Automotive Manufacturing Technology and Material Show